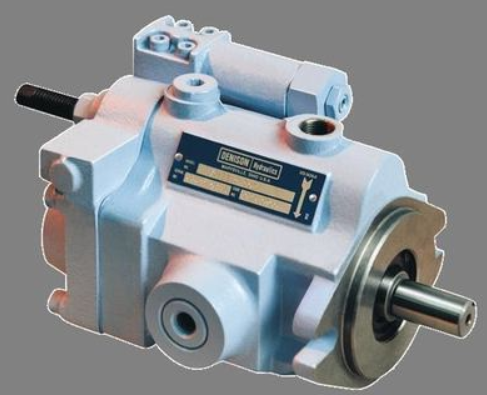

The service life of Denison axial piston pump is related to normal maintenance, quantity and quality of hydraulic oil, cleanliness of oil, etc. It is also a useful way to extend the life of Denison axial piston pump to prevent the abrasion caused by particles in oil. A&S Hydraulic Parts Co., Ltd. after-sales service product maintenance engineer Kimber suggested that parts should be replaced as easily as possible during maintenance. Although these parts are more expensive than other counterfeit parts, they are of better quality and stability. If you buy self-made counterfeit parts at a price, it seems that it saves usage in the short term, but it brings hidden dangers, which may also be right. The use of Denison axial piston pump causes more harm.

Denison axial piston pump with refueling pump is used. After 3000 hours, the operator has to check Denison axial piston pump 1-2 times a day to check whether the sound of hydraulic pump is normal. If the hydraulic cylinder speed drop or stuffy car is invented, it is necessary to check the breakdown of the refueling pump, check whether there are scratches on the edge of the impeller and whether the clearance of the internal gear pump is too large. For self-suction plunger pumps, the oil in the hydraulic tank shall not be lower than the lower limit of the oil mark, and a sufficient number of standard hydraulic oil shall be connected. The higher the cleanliness of hydraulic oil, the longer the service life of hydraulic pump.

The most tense part of Denison axial piston pump is the bearing. If there is clearance in the bearing, the normal clearance of three pairs of friction pairs in the cladding hydraulic pump can not be equal. At the same time, the thickness of hydrostatic supporting oil film of each friction pair will be smashed, and the service life of the bearing of the plunger pump will be reduced. According to the information provided by the hydraulic pump manufacturer, the uniform service life of the bearing is 10,000 hours, so it is necessary to replace the new outlet to override this value. Removal of bearings, there is no professional testing equipment can not detect the clearance of bearings, can only accept visual inspection, such as the invention of scratches or discoloration roller appearance, it must be replaced.

When replacing bearings, the original bearing should be carefully written in English and the type. Most of the plunger pump bearings accept large load capacity bearings. It is better to purchase the original manufacturer and the original specifications. If replacing another brand, we should consult the staff who have the experience of bearing to check the table and adjust it. The goal is to link the precision grade and load capacity of bearings.

Denison axial piston pump can also use frequency converter to save energy. In the actual production process, Denison axial piston pump usually operates under the environment of pressure or flow to regulate the state of affairs. When the actual pressure is greater than the necessary pressure, it is through the relief valve to regulate, so that its work pressure is firmly linked and let the relief valve put over the department. And the motor is running at full speed, repetitive action, power consumption is stable.

The distribution plate has two situations: plane distribution and spherical distribution. The friction pair of spherical flow distribution should be repaired by grinding ability when the scratch ratio of the flow distribution surface of the cylinder block is shallow; when the groove of the flow distribution surface of the cylinder block is deeper, the ability of "appearance engineering skills" should be adopted to fill the groove first, then grinding should be carried out without blindly grinding, in order to prevent the copper layer from thinning or oil leaking out of the steel base.

When accepting overflow to regulate pressure and flow, the surplus overflow of some departments returns to the original system, resulting in a low diligence rate of plunger pumps. If the Chuangjie energy-saving converter is used, the overflow valve can be set to shut down. Through the energy-saving converter itself, it can actively mediate the pressure of things, link the stability of the pressure of things, and actively track the pressure of equipment deployment. Active control is realized to save energy consumption. The greatest advantage of this method is that it can reduce the running energy consumption of Denison axial piston pump and save more than 30% electricity.